Home / Contact Us / About Us / Our Services / North Yorkshire / East Riding Yorkshire / South Yorkshire / West Yorkshire / Greater Manchester / Derbyshire / Reference / FAQ

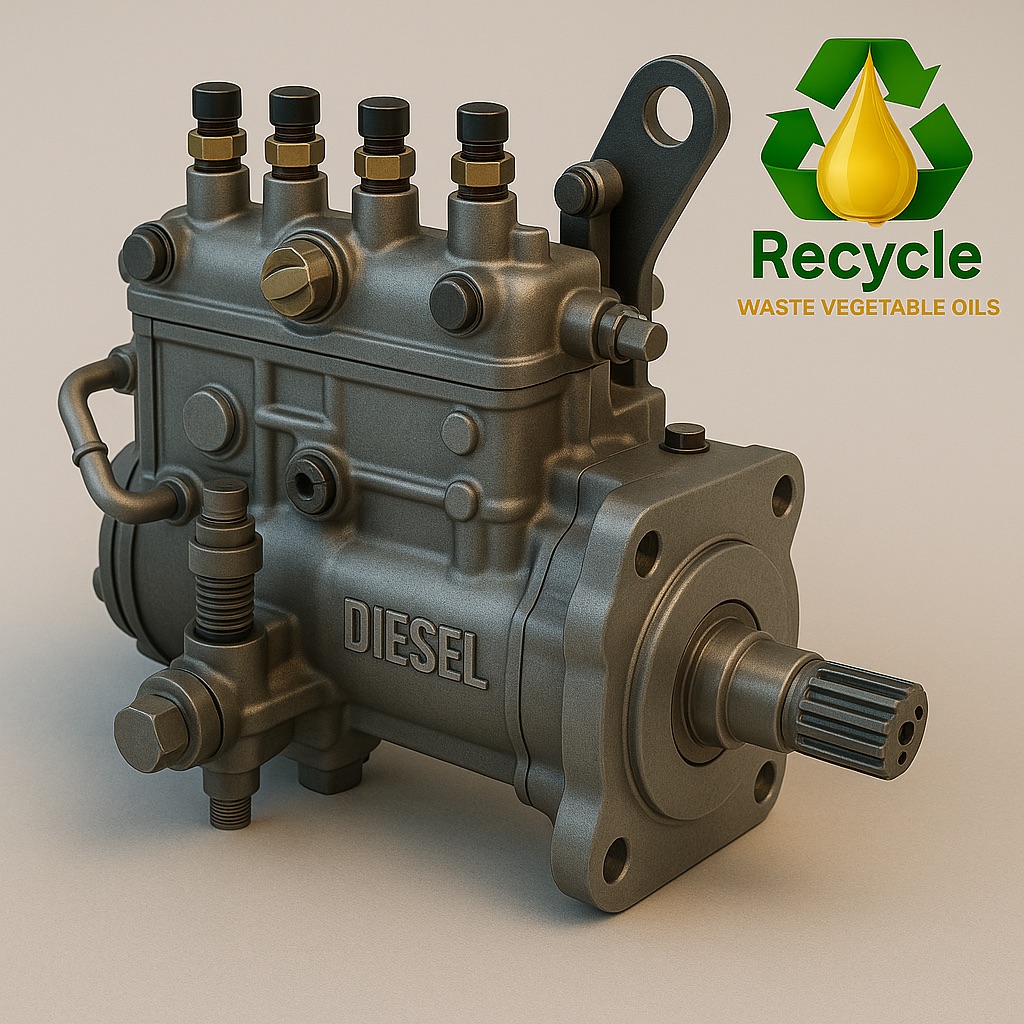

Modern Diesel Pump Innovations & Biofuel Adaptation

As the global demand for cleaner, sustainable fuel sources grows, diesel engine technology has undergone significant transformation. One of the most notable developments is the advancement of diesel fuel injection pumps to support alternative fuels, particularly biodiesel and renewable diesel derived from waste vegetable oils and animal fats.

Why Diesel Pumps Must Evolve

Traditional diesel injection systems were engineered for petroleum-based fuels. However, biofuels such as FAME-based biodiesel and HVO (hydrotreated vegetable oil) differ in viscosity, lubricity, and solvent activity. This has pushed manufacturers to reengineer pumps to handle these characteristics without compromising performance or longevity.

Biofuel-Compatible Pump Materials

Modern diesel pumps now utilize corrosion-resistant alloys, fluorocarbon seals, and chemically inert components that prevent degradation when exposed to high biodiesel blends. Biodiesel's oxygen content and residual glycerin can corrode standard rubber and polymer based parts, leading to early failure if not upgraded.

Smart Injection Technology

One major innovation in diesel pumps is the integration of electronic control units (ECUs). These systems dynamically adjust fuel injection timing, volume, and pressure based on combustion conditions. This allows biofuels, which often have a higher cetane rating and different combustion profiles, to burn more efficiently.

IoT-enabled pumps now communicate real-time data back to operators, providing performance feedback, early warning diagnostics, and predictive maintenance scheduling. This is essential for fleets using variable-quality fuels or mixed blends across regions and seasons.

Adaptation to Renewable Diesel (HVO)

Unlike traditional biodiesel, HVO is a hydrocarbon that mimics petroleum diesel. It's refined through a hydrogenation process from waste vegetable oils, making it a clean, drop-in replacement for standard diesel.

Major engine manufacturers such as Cummins and Scania have approved HVO for use in their engines without the need for hardware modifications. Diesel pumps used with HVO experience reduced wear due to the fuel’s high cetane number and exceptional combustion efficiency.

Biodiesel Challenges & Solutions

Although biodiesel is environmentally friendly and renewable, it presents several technical challenges:

- Cold flow issues in low temperatures

- Higher likelihood of injector deposits

- Fuel filter clogging from impurities

- Seal and gasket wear from oxidized fuel

To overcome these, many systems now include fuel heaters, dual-tank setups (for starting on diesel and switching to biofuel), and advanced fuel filtration. Manufacturers have also improved pump clearance tolerances to accommodate biodiesel’s higher viscosity.

Unit Injector & Camless Systems

In heavy-duty and marine applications, diesel engines are moving toward camless and electronically controlled unit injectors. These provide precise fuel metering at extremely high pressures, improving atomization and combustion.

This high precision is beneficial when using biodiesel or blends with non-uniform properties, ensuring complete combustion and lower emissions. These systems are also more adaptable to future biofuels that may emerge from algae, biomass, or synthetic sources.

Waste Vegetable Oil as a Fuel

Filtered and pre-treated waste vegetable oil (WVO) is gaining traction among off-grid users and sustainability-focused businesses. While not suitable for all modern diesel engines without modifications, older indirect-injection engines or those with aftermarket WVO conversion kits can run effectively on it.

Diesel pumps adapted for WVO typically include:

- Heated lines and pumps to reduce viscosity

- Upgraded seals and gaskets

- Inline micro-filtration

- Dual-fuel switching controls

Global Market Trends

Government mandates are accelerating the adoption of biofuel compatible pumps. The US EPA’s Renewable Fuel Standard (RFS) and Europe's RED II directive have set aggressive blending targets. The diesel pump market is projected to grow steadily through 2030, with strong demand for bio-ready systems.

Fleet operators and municipalities are also driving demand by seeking lower emissions, reduced maintenance, and extended engine life through biofuels. This shift is especially visible in waste management, agriculture, and transport industries.

Looking Ahead

The future of diesel injection systems is rooted in flexibility and intelligence. Pumps are no longer one-size-fits-all components. They’re smart, durable, and capable of adapting to a wide range of renewable fuels. Whether running on clean-burning HVO or filtered waste oil, modern diesel pumps are central to bridging the gap between today’s engines and tomorrow’s sustainability goals.

Conclusion

With the rise of biofuels and stricter emissions regulations, the diesel fuel pump is transforming from a passive component into a high-tech, fuel-agnostic system. This evolution not only enhances engine performance but also supports the global transition to low-carbon energy solutions. Businesses, mechanics, and sustainability advocates alike must stay informed and invest in compatible technologies to remain future-ready.